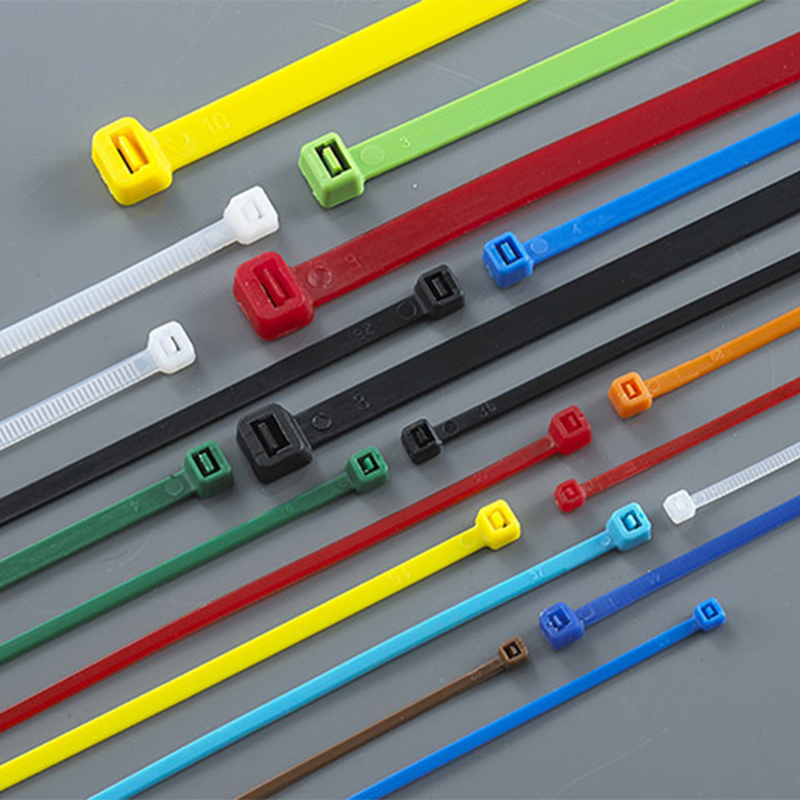

Colorful Plastic Self-locking Nylon Cable Ties 4.8*300mm

Detail

1. Material: Nylon 66, 94V-2 certificated by UL,brand ASCEND and INVISTA

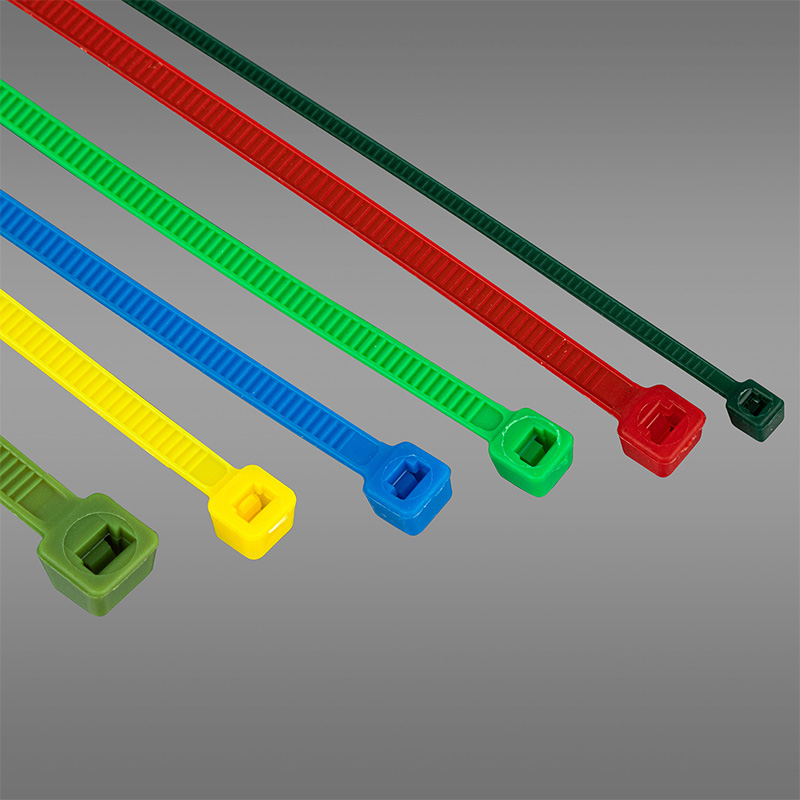

2. Color: Natural (white), black and colorful.

3. Available size:

Width 2.5mm with length 80mm-200mm

Width 3.6mm with length 100mm-370mm

Width 4.8mm with length 100mm-650mm

Width 7.6mm with length 150mm-550mm

Width 8.8mm with length 400mm-1020mm

4. Usage: Widely used for household,electricity,auto parts,hardware etc.Wide application of computer, TV, air-conditioning production, control engineering wiring, household appliances, lighting, electrical, electronic toys and other products or wire fixed, mechanical equipment oil pipeline is fixed, fixed cable lines on the ship, the whole bike vehicle packaging or bundling other objects, can also be used for agriculture, horticulture, handicrafts and other bundled items.

5. Certification: UL Certification,CE,ROHS,SGS Test Report.

6. Operating Temperature: -40℃ to 85℃.

7. Feature: Acid, Erosion Resistant, Good Insulation and not apt to age.

8. Packing Detail:

A.Common Packing: 100Pcs + Polybag + Label + Export Carton.

B.Customized Packing: Header card packing, Blister with card packing,or as customized.

C.Perfect package according to your demand.

9. Delivery time: In 7-30 days after receiving deposit,according to order quantity,as we have automatic production line and profession workers

10. Payment Terms: T/T,L/C,Western Union,PayPal.

11. Loading port: NINGBO or SHANGHAI PORT

12. Tensile strength: 18-250LBS

13. Brand: HDS or OEM package

14. Injection Molds: Hot Runner Molds+Central material provided system

15. Injection machines: 12 sets injection machines,large production capacity

16. After-sales service: We offer perfect after-sales service to protect the rights and interests of each customer.

17. Export countries to: 50 different countries. Such as Russia,Japan,Vietnam,Argentina,Brazil,Ukraine,Singapore,Thailand,Australia,Turkey, Korea,Malaysia,Korea,Malaysia,Poland and so on. Some of our customers cooperated with our company for more than 10 years,like our customs from Japan,Russia and Turkey.

18.

01. Cable tie Application: For indoor and outdoor use. A variety of materials and colors is available for specific applications.

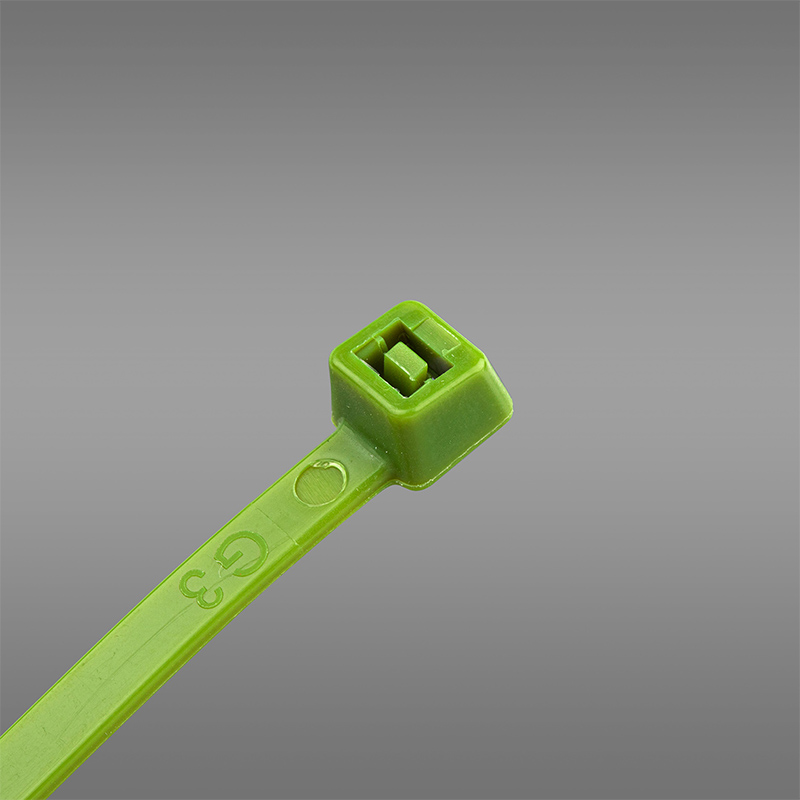

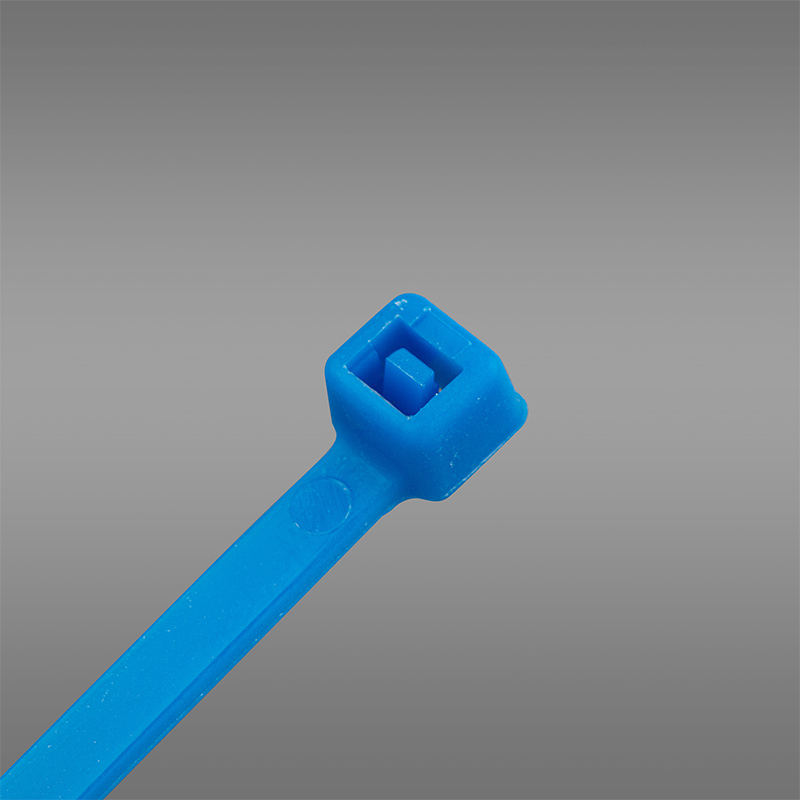

02. Cable tie Using Instruction:

One-piece construction for consistent performance and reliability. Lowest threading force of any one-piece cable tie in the industry.

Curved tip is easy to pick up form flat surfaces and allows faster initial threading to speed installation.

Samples is available to send to check our quality!

Specifications

|

Type |

L |

W(mm) |

Max.Bundle Dia.(mm) |

Min tensile strength |

||

|

Inch |

mm |

Ibs |

kgs |

|||

|

HDS-3x60 |

2 3/8" |

60 |

2.5 |

11 |

18 |

8 |

|

HDS-3x80 |

3 3/16" |

80 |

2.5 |

16 |

18 |

8 |

|

HDS-3x100 |

4" |

100 |

2.5 |

22 |

18 |

8 |

|

HDS-3x120 |

4 3/4" |

120 |

2.5 |

30 |

18 |

8 |

|

HDS-3x150 |

6" |

150 |

2.5 |

35 |

18 |

8 |

|

HDS-3x160 |

6 1/4" |

160 |

2.5 |

40 |

18 |

8 |

|

HDS-3x200 |

8" |

200 |

2.5 |

50 |

18 |

8 |

|

HDS-4x100 |

4" |

100 |

3.5 |

22 |

40 |

18 |

|

HDS-4x120 |

4 3/4" |

120 |

3.5 |

30 |

40 |

18 |

|

HDS-4x150 |

6" |

150 |

3.5 |

35 |

40 |

18 |

|

HDS-4x180 |

7" |

180 |

3.5 |

42 |

40 |

18 |

|

HDS-4x200 |

8" |

200 |

3.5 |

50 |

40 |

18 |

|

HDS-4x250 |

10" |

250 |

3.5 |

65 |

40 |

18 |

|

HDS-4x300 |

11 5/8" |

300 |

3.5 |

80 |

40 |

18 |

|

HDS-4x370 |

14 1/2" |

370 |

3.5 |

102 |

40 |

18 |

|

HDS-5x100 |

4 |

100 |

4.8 |

22 |

50 |

22 |

|

HDS-5x120 |

4 3/4" |

120 |

4.8 |

30 |

50 |

22 |

|

HDS-5x150 |

6" |

150 |

4.8 |

35 |

50 |

22 |

|

HDS-5x180 |

7" |

180 |

4.8 |

42 |

50 |

22 |

|

HDS-5x200 |

8" |

200 |

4.8 |

50 |

50 |

22 |

|

HDS-5x250 |

10" |

250 |

4.8 |

65 |

50 |

22 |

|

HDS-5x300 |

11 5/8" |

300 |

4.8 |

82 |

50 |

22 |

|

HDS-5x350 |

13 3/4" |

350 |

4.8 |

90 |

50 |

22 |

|

HDS-5x380 |

15" |

380 |

4.8 |

102 |

50 |

22 |

|

HDS-5x400 |

15 3/4" |

400 |

4.8 |

105 |

50 |

22 |

|

HDS-5x430 |

17 3/4" |

430 |

4.8 |

120 |

50 |

22 |

|

HDS-5x450 |

17.7" |

450 |

4.8 |

125 |

50 |

22 |

|

HDS-5x500 |

19 11/16" |

500 |

4.8 |

150 |

50 |

22 |

|

HDS-5x530 |

20" |

530 |

4.8 |

155 |

50 |

22 |

|

HDS-8x150 |

6" |

150 |

7 |

35 |

120 |

55 |

|

HDS-8x180 |

7" |

180 |

7 |

42 |

120 |

55 |

|

HDS-8x200 |

8" |

200 |

7 |

50 |

120 |

55 |

|

HDS-8x250 |

10" |

250 |

7 |

65 |

120 |

55 |

|

HDS-8x300 |

11 5/8" |

300 |

7 |

82 |

120 |

55 |

|

HDS-8x350 |

13 3/4" |

350 |

7 |

90 |

120 |

55 |

|

HDS-8x370 |

14 1/2 " |

370 |

7 |

102 |

120 |

55 |

|

HDS-8x400 |

15 3/4" |

400 |

7 |

105 |

120 |

55 |

|

HDS-8x450 |

17 3/4" |

450 |

7 |

118 |

120 |

55 |

|

HDS-8x500 |

19 11/16 " |

500 |

7 |

150 |

120 |

55 |

|

HDS-8x550 |

21 4/5 " |

550 |

7 |

165 |

120 |

55 |

|

HDS-10x400 |

15 3/4" |

400 |

8.8 |

105 |

175 |

80 |

|

HDS-10x450 |

17 3/4" |

450 |

8.8 |

118 |

175 |

80 |

|

HDS-10x500 |

19 11/16 " |

500 |

8.8 |

150 |

175 |

80 |

|

HDS-10x550 |

21 11/16 " |

550 |

8.8 |

165 |

175 |

80 |

|

HDS-10x650 |

25 9/16 " |

650 |

8.8 |

190 |

175 |

80 |

|

HDS-10x760 |

29 1/2 " |

760 |

8.8 |

220 |

175 |

80 |

|

HDS-10x800 |

31 1/2 " |

800 |

8.8 |

230 |

175 |

80 |

|

HDS-10x900 |

36 1/4 " |

900 |

8.8 |

265 |

200 |

90 |

|

HDS-10x1020 |

40 1/6 " |

1020 |

8.8 |

292 |

200 |

90 |

|

HDS-10x1200 |

48" |

1200 |

8.8 |

345 |

200 |

90 |

|

HDS-12x650 |

25 3/5 " |

650 |

11 |

165 |

250 |

114 |

|

HDS-12x760 |

35 1/2 " |

760 |

11 |

225 |

250 |

114 |