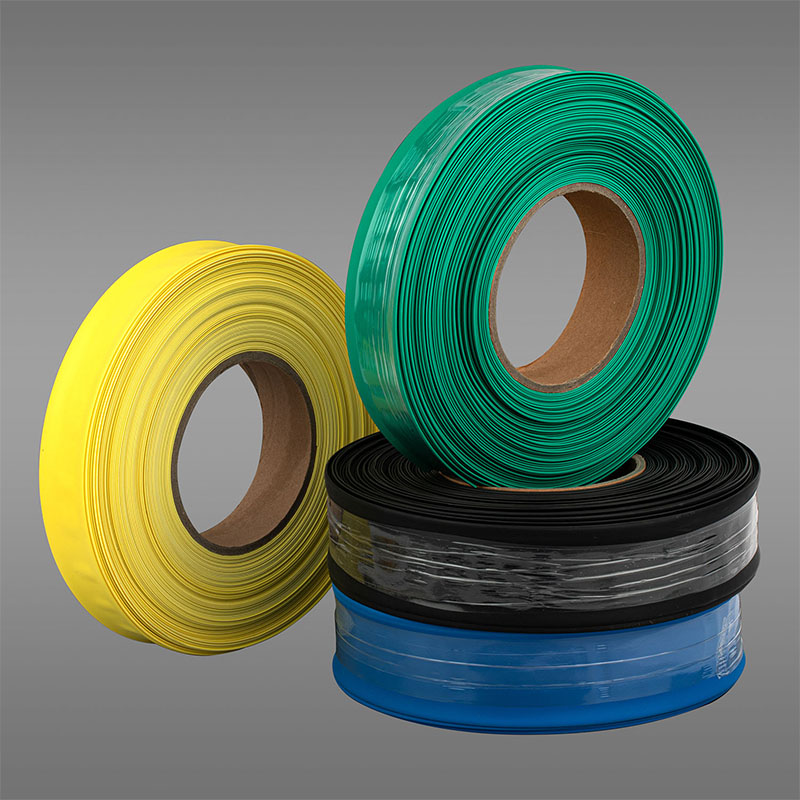

yellow color Heat Shrinkable Tubings sleeves for gas pipe 25mm

Characteristics

1.Material: Polyolefin

2.Color: Black,red, blue,white,yellow,green and transparent,other colors can be customized

3.Usage: widely used in wire connection welding protection wire marking the insulation protection of resistance and capacitor the corrosion protection of metal bar or tubes and the antenna protection.

4.Certification: UL,CE,ROHS,SGS Test Report.

5.Diameters available: from Ø2mm to Ø180mm

6.Shrinking ratio: 2:1

7.Initial shrinking temperature: 70℃.

8.Full shrinking temperature: 125℃.

9.Rated voltage: 600V

10.Safety standard: FT2, RoHS

11.Delivery time: In 7 -25 days after receiving ,according to order quantity.

12.Payment Terms: T/T,L/C,Western Union,PayPal.

Samples is available to send to check our quality!

Specifications

|

Specification |

Dimension before shrinking(mm) |

Dimension after shrinking (mm) |

Standard packaging (m/disc)

|

Application (mm)

|

||

|

Internal diameter |

Wall thickness |

Internal diameter |

Wall thickness |

|||

|

Φ2.0 |

2.2±0.3 |

0.25±0.05 |

0.98±0.1 |

0.32±0.05 |

200 |

1.1~1.8 |

|

Φ2.5 |

2.6±0.3 |

0.25±0.05 |

1.23±0.2 |

0.35±0.05 |

200 |

1.35~2.3 |

|

Φ3.0 |

3.2±0.4 |

0.25±0.05 |

1.45±0.2 |

0.35±0.05 |

200 |

1.6~2.7 |

|

Φ3.5 |

3.6±0.4 |

0.25±0.05 |

1.72±0.2 |

0.35±0.05 |

200 |

1.85~3.2 |

|

Φ4.0 |

4.2±0.4 |

0.25±0.05 |

1.96±0.2 |

0.35±0.05 |

200 |

2.1~3.6 |

|

Φ4.5 |

4.6±0.4 |

0.25±0.05 |

2.20±0.2 |

0.35±0.05 |

200 |

2.35~4.0 |

|

Φ5.0 |

5.2±0.4 |

0.25±0.05 |

2.48±0.2 |

0.35±0.05 |

200 |

2.6~4.5 |

|

Φ6.0 |

6.2±0.4 |

0.28±0.15 |

2.96±0.3 |

0.45±0.15 |

200 |

3.1~5.4 |

|

Φ7.0 |

7.2±0.4 |

0.28±0.15 |

3.48±0.3 |

0.45±0.15 |

100 |

3.7~3 |

|

Φ8.0 |

8.2±0.5 |

0.28±0.15 |

3.95±0.3 |

0.45±0.15 |

100 |

4.2~7.2 |

|

Φ9.0 |

9.2±0.5 |

0.30±0.15 |

4.40±0.3 |

0.50±0.15 |

100 |

4.7~8.0 |

|

Φ10 |

10.2±0.5 |

0.30±0.15 |

4.90±0.3 |

0.50±0.15 |

100 |

5.2~9.0 |

|

Φ11 |

11.2±0.5 |

0.30±0.15 |

5.40±0.3 |

0.50±0.15 |

100 |

5.7~10 |

|

Φ12 |

12.2±0.5 |

0.30±0.15 |

5.90±0.5 |

0.50±0.15 |

100 |

6.2~11 |

|

Φ13 |

13.2±0.5 |

0.33±0.15 |

6.40±0.5 |

0.50±0.15 |

100 |

6.7~12 |

|

Φ14 |

14.2±0.5 |

0.35±0.15 |

6.90±0.5 |

0.50±0.15 |

100 |

7.3~13 |

|

Φ15 |

15.2±0.6 |

0.38±0.15 |

7.40±0.5 |

0.60±0.15 |

100 |

7.8~14 |

|

Φ16 |

16.2±0.6 |

0.38±0.15 |

7.90±0.5 |

0.60±0.15 |

100 |

8.3~15 |

|

Φ17 |

17.2±0.6 |

0.38±0.15 |

8.40±0.5 |

0.60±0.15 |

100 |

8.8~16 |

|

Φ18 |

18.2±0.6 |

0.40±0.15 |

8.90±0.5 |

0.60±0.15 |

100 |

9.3~17 |

|

Φ20 |

20.2±0.8 |

0.40±0.20 |

9.90±0.5 |

0.70±0.20 |

100 |

11.4~19 |

|

Φ22 |

22.2±0.8 |

0.42±0.20 |

10.80±1.0 |

0.70±0.20 |

100 |

12.4~21 |

|

Φ25 |

25.3±0.8 |

0.45±0.20 |

12.30±1.0 |

0.70±0.20 |

50 |

12.8~24 |

|

Φ28 |

28.3±0.8 |

0.45±0.20 |

13.50±1.0 |

0.70±0.20 |

50 |

14.4~29 |

|

Φ30 |

30.2±0.8 |

0.45±0.20 |

14.70±1.0 |

0.70±0.20 |

50 |

16~29 |

|

Φ35 |

35.2±0.8 |

0.50±0.20 |

17.30±1.0 |

0.80±0.20 |

50 |

18~34 |

|

Φ40 |

40.0±1.0 |

0.50±0.20 |

19.80±1.0 |

0.80±0.20 |

50 |

21~39 |

|

Φ50 |

50.0±1.0 |

0.50±0.20 |

24.80±1.0 |

0.80±0.20 |

50 |

26~49 |

|

Φ60 |

60.0±1.0 |

0.60±0.20 |

29.80±1.0 |

0.80±0.20 |

25 |

35~55 |

|

Φ70 |

70.0±1.0 |

0.65±0.20 |

34.00±2.0 |

1.00±0.20 |

25 |

40~65 |

|

Φ80 |

80.0±1.0 |

0.65±0.20 |

39.00±2.0 |

1.00±0.20 |

25 |

45~75 |

|

Φ90 |

90.0±1.0 |

0.65±0.20 |

44.00±2.0 |

1.00±0.20 |

25 |

50~88 |

|

Φ100 |

100.0±2.0 |

0.65±0.20 |

49.00±2.0 |

1.00±0.20 |

25 |

55~95 |

|

Φ120 |

120.0±2.0 |

0.70±0.20 |

59.00±2.0 |

1.20±0.20 |

25 |

65~115 |

|

Φ150 |

150.0±2.0 |

0.70±0.20 |

74.00±2.0 |

1.20±0.20 |

25 |

80~145 |

|

Φ180 |

180.0±2.0 |

0.70±0.20 |

88.00±2.0 |

1.20±0.20 |

25 |

95~175 |